The combination of water usage and energy usage in open-loop cooling towers is a significant cost to owners. There are ways to reduce the waste …

“What is Pulse Technology?” and “Why We Use it to Affect Water Quality.” – Part 3

The objective of water treatment is to:

*INHIBIT CORROSION, prevent mineral scale & control bacteria, biofilm & legionella. In this Monday Morning Minute, we will discuss the technology and the effect that pulse technology via the Griswold Wave product provides specific to corrosion inhibition.

“What is Pulse Technology?” and “Why We Use it to Affect Water Quality.” – Part 2

The objective of water treatment is to: *CONTROL BACTERIA, BIOFILM AND LEGIONELLA, Inhibit Corrosion, & Prevent Mineral Scale. In this Monday morning minute, we will discuss the technology and the effect that pulse technology via the Griswold Wave product provides specific to microbial control.

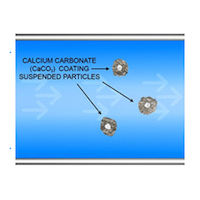

“What is Pulse Technology?” and “Why We Use it to Affect Water Quality.” – Part 1

The objective of water treatment is to: PREVENT MINERAL SCALE*, Control Bacteria, Biofilm And Legionella, & Inhibit Corrosion. In this Monday morning minute, we will discuss the technology and effect that pulse technology via the Griswold Wave product provides specific to mineral scale prevention.

Strategies for Water Use Efficiency – Cooling Tower Selection – Part V

Today’s building owner’s have many opportunities to improve water use efficiency. ASHRAE Standard 189.1 identifies a few areas to focus on reducing water use specific to cooling towers. The last four issues of Deppmann’s Monday Morning Minutes has discussed specific strategies to improve water use efficiency using current Cooling Tower and Advanced Water Treatment technology advancements in design. [Read more…]

Strategies for Water Use Efficiency – Cooling Tower Selection – Part IV

Most new chillers can now handle variable flow through the condenser providing many opportunities for operational savings. As the cooling tower is an integral part of this system, it is important to understand the effect of flow rate changes and how to insure your cooling tower can provide optimal savings while operating [Read more…]

Strategies for Water Use Efficiency – Cooling Tower Selection – Part III

In this issue, we will discuss the changing requirements specific to “cycles of concentration” in cooling tower applications. In addition, we will review the effect of increasing cycles of concentration and provide solutions to improving these results. ASHRAE Standard 90.1-2010 code change effective 10.18.2013 states [Read more…]

Strategies for Water Use Efficiency – Cooling Towers – Part II

In this issue, we will discuss blow down and cycles of concentration. In addition to water emissions caused by evaporation and drift, cooling towers require blow-down to control the levels of dissolved minerals re-circulated in the cooling tower. These losses are offset or balanced by make up water to both maintain the level of water in the tower and more importantly, [Read more…]

Strategies for Water Use Efficiency – Cooling Tower Selection – Part 1

Open loop evaporative type Cooling Towers by design create emissions of evaporation and drift. Drift emissions from open-loop evaporative type cooling towers are unavoidable. Stand next to a conventional cooling tower and it feels like you might be taking a shower. The amount of drift can vary depending on tower design and will include any water treatment added (chemicals). [Read more…]

- Page 2 of 2

- 1

- 2