In the last R. L. Deppmann Monday Morning Minutes (MMM), we introduced the basic concept of an HVAC variable speed pump control head, modeling a simple single coil example. Let’s look at control head with a more complicated system.

Control Head Varies Based on System Location

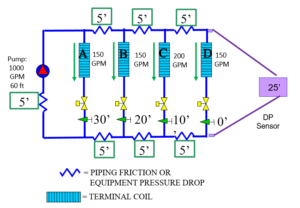

The variable speed pump control head varies depending on where the sensor is located. Last week, we used a pumping system with a capacity of 650 GPM at 60 feet with a single coil. Let’s use the same pump and show a representation of a larger hydronic system.

To make this easier to look at, I made all the coil and two-way control valve pressure drops the same 25 feet. If they differed, only the balance valve numbers would change. Notice the manual balance valves are throttled and the system is in balance.

The control head is often the farthest zone. In our example, that is Zone D. There are pipe friction losses between the zones and in the mechanical equipment room that adds up to (7′ X 5′ = 35’). The control head is 25’, so the total head is 25’ + 35’ = 60’.

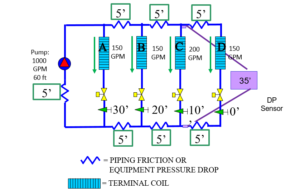

So what happens if we move the differential sensor closer to the mechanical equipment room? What if we locate it across zone C?

If the DP sensor is located across Zone C, the required pressure drop downstream of the sensors is (25 + 5 + 5 =) 35 feet. If we move it to Zone B, the control head would be 45’. Zone A would be 55’, the same as putting the DP sensor in the mechanical room across the supply and return. Finally, if the DP sensor is located across the pump, the control head would be 60 feet – just like we described in the last MMM. What effect does the location have on energy use?

Variable Speed Pump Sensor Location and Energy Costs

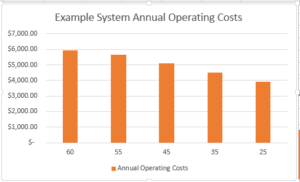

We showed last week that DP sensor location has a direct effect on energy costs in a variable flow hydronic system. We can use the Bell & Gossett ESP-Systemwize program to see how the DP sensor setpoint affects the operating costs. Here’s one screenshot of the variable speed pump selected and modeled with a 60-foot control head:

The savings are significant if the DP sensor is properly located. In this example, based on the PLEV loading, you can save almost $2,000 per year by placing the differential sensor feedback in the right place.

Next week, the R. L. Deppmann Monday Morning Minutes will present a series of fast technical topics at our Open House in Novi, Michigan on June 27, 2018.