Hydronic closed systems are normally clean, and dirt issue are rare. There are times when an older system may have dirt and particulate. How does the contractor and engineer offer solutions to the owner when particulate is the issue? Today we look at three methods that will work in both side stream and single pass installations.

Combination Air-Dirt Separator Review

In the last R. L. Deppmann Monday Morning Minutes, Air and Dirt Separators in Closed Hydronic Systems, we looked at the air/dirt separator. This product is great in closed hydronic systems where dirt is the primary culprit. These separators work well if you are putting an addition on an older system and are concerned with the water quality in that system. In brand new systems, the Bell & Gossett Rolairtrol air separator is a better solution since air is the prime culprit. The Rolairtrol air separator has significantly higher air removal percentage per pass which will get the air out fast. Visit Air Separators in Closed Hydronic Systems for more information.

What happens if you need more immediate dirt removal or fine separation of dirt and fluid? Read on.

Full Line Size Y-Strainers

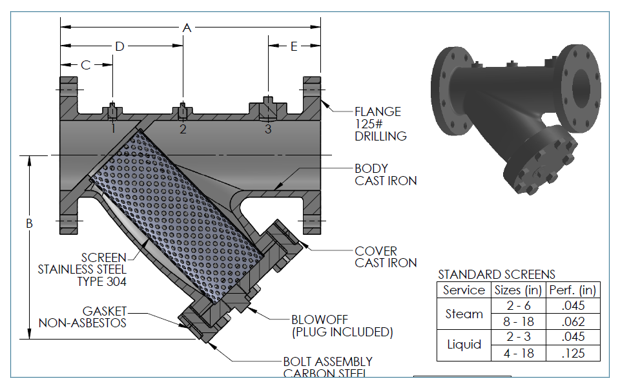

The oldest and simplest technology used to capture particulate is the strainer. The strainer is simply a housing with a basket or cylinder inside with holes in it. The size of the hole determines what size particulate will get through it. It is simple and comes in two main types: The Y-strainer and the basket strainer.

The important thing about Y-strainers is the size of the openings in them. The size of the holes is specified in perforation diameter. Look at the representation above of a Y-strainer from Basket Strainers and Energy-Efficient Style Y-Strainers from Metraflex. For liquids in a hydronic system, the larger size over 4” will have 1/8” holes. This size is good enough for most issues that may show up in the system.

There are times when a smaller particulate size will become an issue. Strainers come in a variety of basket diameter holes. Remember that there may be a longer lead time and there should be an indication on the job site in case the strainer is ever replaced. For example an use of a strainer with a smaller hole diameter, visit Water Side Economizers: Heat Exchanger Fouling & Maintenance and look at the issue of plate heat exchangers. Do not forget that smaller holes mean higher pressure drops.

When you have a need for tight dirt control, the nomenclature turns to “mesh.” A 20-mesh strainer has about 1/32” holes. These are great for startup but a maintenance nightmare if left in the system. Visit these links for more on Y-strainers. New LPD Strainer Design Saves Energy Usage vs Basket Strainers and Steam & Condensate Strainers: Steam & Steam Heat Exchanger Basics Part 11.

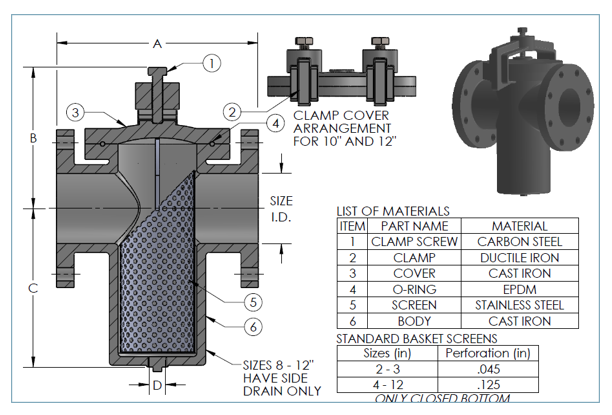

Basket Strainers

Use basket strainers when you need to be able to empty the strainer quickly and when you have large volumes of particulate. These are normally not found in closed systems. You will most often find them in open cooling tower systems in buildings. A clamp cover will make the maintenance significantly faster.

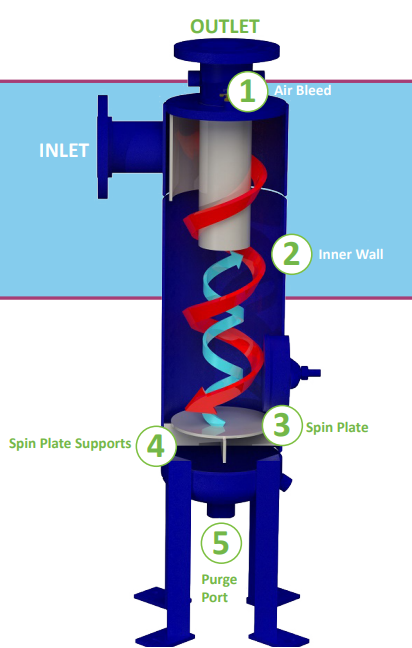

Cyclone Separators

Cyclone separators, such as the General Water Systems Filtration product shown here, are very efficient. They use the same centrifugal principle as the Rolairtrol to spin the heavier dirt and separate it from the water. They may show up in the main line for a high first-pass percentage removal or used in a side stream application. These require a minimum pressure drop of 3 to 6 PSIG caused by the flow rate. They would not work continuously in a variable speed hydronic system at full line size unless you provide a separate pump to maintain the flow rate. In those applications, we recommend a system approach such as a packaged piece of equipment.

Media Filters

We mention filters since they are a true single-pass particulate solver. They are typical in plumbing and process systems but not in a hydronic system. We do see them on pump external flushing lines at times. These would be smaller inline filters for the external seal flushing lines.

Next week we will look at a problem job and show you how we counseled the team to solve the problem.