In part 1 and part 2 of this series, we discussed maximum and minimum heated water velocities in Bell & Gossett SU heat exchangers with standard ¾” tubes, applied to a variable volume, variable speed system. We also gave some recommendations. This week we’re discussing the minimum velocities and suggestions for glycol-based heat transfer fluids.

Minimum Velocity with Glycol-Based Heat Transfer Fluids

When selecting a shell and tube heat exchanger, the goal is to select a heat exchanger with a velocity that is high enough to minimize the size of the exchanger while providing great heat transfer, but not so high as to cause damage if the flow rate exceeds design within a few percent.

In a two-way control valve system with variable flow, the selection should also be reviewed at the minimum flow rate to avoid laminar operation, which leads to cycling of the control valve. Once the flow in a heat exchanger changes from turbulent to laminar, the heat transfer capability drops dramatically. This can cause the control valve to start acting more like an on-off valve than a modulating valve, resulting in poor temperature control as well as more maintenance and repair costs. In a Bell & Gossett SU or WU heat exchanger with standard ¾” copper tubes, what is the minimum velocity to remain turbulent? This isn’t a great concern when using water, but what about glycols?

The heat transfer properties of fluids such as Dow Chemical’s Dowfrost™ and Dowtherm™ are different than water. The minimum velocity to keep turbulent flow is also different.

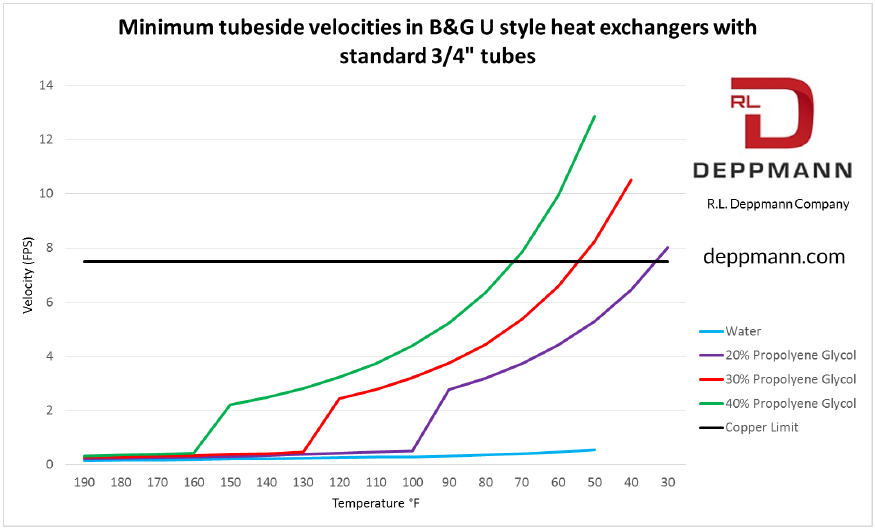

The following chart shows the minimum velocity needed at various temperatures to maintain turbulent flow in heat exchangers with ¾” standard copper tubes. Enter the chart on the horizontal at the average temperature of the fluid and read up to the line that matches your fluid percent P.G. Read to the left to find the minimum velocity to maintain turbulent flow. I added a black limitation line for the maximum velocity in copper tubes. If you are above the black line, contact us to change materials of construction.

Let’s look at an example: Assume we have a steam-to-glycol heat exchanger selection with 30% DowFrost (Propolyene glycol). The system has a turndown ratio from the design average temperature of 180°F down to an average of 110°F. Let’s also assume you used our recommendations and selected at 6 FPS velocity. Your system has 2-way valves and the minimum flow is 20% of the design flow rate, or a 5:1 turndown of flow. What is the minimum velocity to remain turbulent?

Looking at the chart above, I read 110°F on the horizontal axis and read up to the 30% PG line. Read across to the minimum velocity and we see the answer is about 2.7 FPS. This is greater than the 1.2 FPS minimum you wanted. The solution is to call your B&G representative for optional materials/tube design or to change to a primary secondary system as recommended below.

Avoiding Minimum Velocity Issues with Glycol-Based Heat Transfer Fluids

Bell & Gossett engineers provide a number of options to help avoid problems caused by heat exchangers. Contact your B&G representative, who will work with factory engineers to select the correct combination of tube materials, diameters, and thickness for your specific application.

Another suggestion is to consider using a primary secondary system. Similar to many boiler systems, make the flow rate to the heat exchanger constant and select the heat exchanger to keep the velocity high through the intended temperature range of operation.