This week and next we will talk about centrifugal pumps with the variable speed technology built into them. These pumps are called “Smart pumps.” Why are these pumps better than a standard pump and motor with a variable frequency drive or VFD mounted on the wall? We look at the advantages of these smart pumps and talk about inline, line mounted products this week.

What is an Inline Smart Pump?

- Bell & Gossett e-90E Smart Pump

- Bell & Gossett ecocirc XL

You have a requirement for a small inline pump under 5 HP and have multiple pump choices. You want the pump to be variable speed, and your Bell & Gossett (B&G) representative suggests a smart pump. What is a smart pump? Most of these small inline pumps start with an ECM or electronically commutated motor, also known as permanent magnet motors. These motors are much more efficient than traditional AC pump motors.

The ECM motor takes AC power and converts it to DC. The DC power can be varied to change the speed. Visit our previous blog What is an ECM Pump? – Part 1 for a look at these ECM motors.

The smart inline pump may either react to an external control signal or have built in control options.

What Does the Engineer Gain by Specifying Smart Pumps?

Obviously, an engineer could select a traditional B&G line mounted inline pump for the duty. They could then select, specify, and show a wall mounted drive in the documents. What does the smart pump offer the specifying engineer?

The number one item is motor efficiency. Here is a little-known fact: the energy standards for motors are normally for ratings over 1 HP with the standard frames and pump types used for larger pumps. The “booster” series of pumps was not included in the EPACT motor standards or the U.S. pump energy standards. The “booster” series are smaller inline, line mounted, pumps. Some of these motors may have efficiencies less than 60%. The motors may not meet the IEC-3 standards and may be an IEC-1 or 2. These smart pumps use motor technology that has motors that meet either IEC 4 or IEC 5 efficiency standards.

The engineer gains the best efficiency for their client without having to verify for each selection whether a premium efficiency motor is available or not. This avoids a potential huge specification coordination nightmare.

In addition, the engineer gains the unit responsibility of having the variable speed technology and pump by one source. A single contact if there are questions or issues.

These smart pumps may also include more reliable startup, reporting, and owner interaction.

Here are some previous articles we published on this subject of motor efficiency:

- Variable Speed Pump Motors and Drives

- Part 1: Permanent Magnet Motors & Electronically Commutated Motors

- Part 2: Permanent Magnet & Electronically Commutated Motors in Hydronic Systems

- Part 3: The Advantages and Disadvantages of Permanent Magnet Motors

- Motor Specifications for HVAC & Plumbing Building Trades

Let’s look at a couple of line mounted smart pumps from Bell & Gossett:

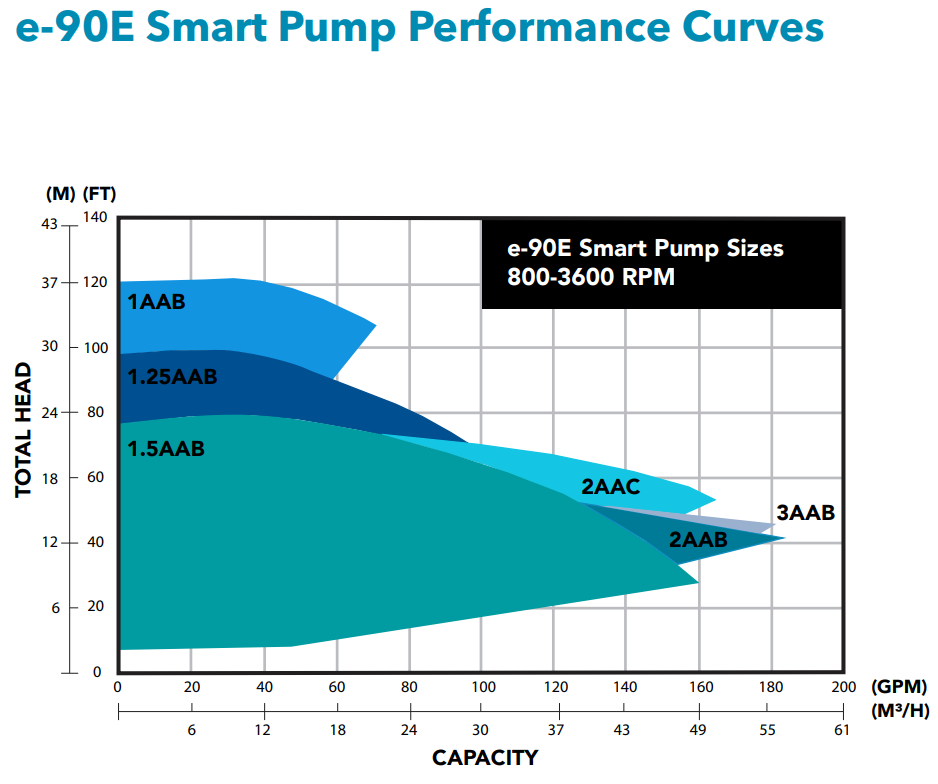

B&G e-90E Smart Line Mounted Pumps

The B&G e-90E smart pump combines the advantages of the ECM motor with a smart controller.

The motor is rated to IEC5 highest efficiency standards.

The drive portion can vary the speed of the motor from 800 to 3600 RPM.

Includes pre-programming for constant pressure and system/control curve operation. It can, of course, respond to an external signal.

Communicates via BACnet or Modbus.

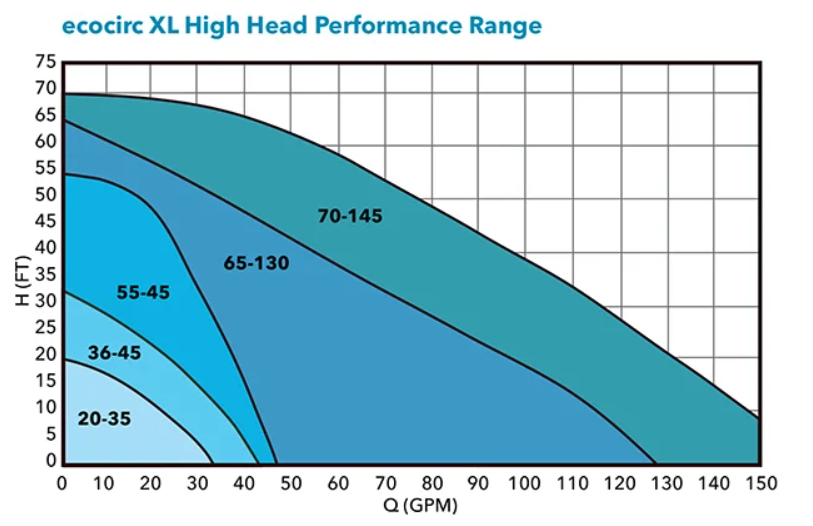

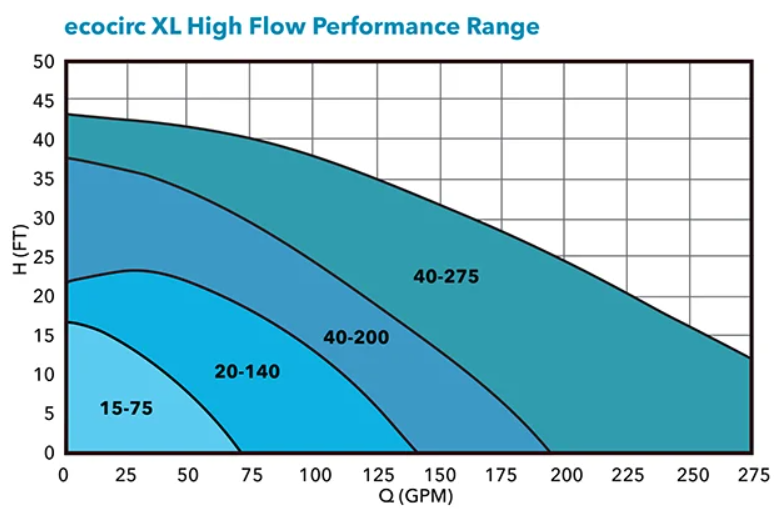

B&G ecocirc XL ECM Smart Line Mounted Pumps

The B&G ecocirc XL is an ECM wet rotor smart pump combining the advantages of the permanent magnet motor with a smart controller.

The motor is available in single and three phase.

The drive portion can vary the speed of the motor down to less than 50%.

Includes pre-programming for constant pressure, constant temperature, and proportional pressure operation. It can, of course, respond to an external signal.

Communicates via BACnet or Modbus.

Next week we will continue to feature smart pumps including a base mounted end suction version of this high efficiency technology.