When looking at pumps, the one question every HVAC and Plumbing engineer will ponder is “which pump do I choose?” There are several factors that lead to the answer to this question. Last week, R.L. Deppmann Monday Morning Minutes (MMM) looked at pump type, NPSH, and motor speed. Today, we finish with the last four steps: pump efficiency, where on the curve to select, room to move, and other considerations. This blog will focus on closed hydronic system selections, but the basic concepts can be used in plumbing and industrial selections. This will be one you want to reference often, so keep the link handy.

Last week we looked at the type of pump to select. There are many types and reasons to use each type. We also looked at net positive suction head, which is an important selection consideration in open systems. Finally, we looked at the speed and type of motor available. Now we continue by looking at the thing most engineers talk about, efficiency.

Step Four: Pump Efficiency

Why did we wait so long to discuss efficiency? The efficiency of a pump may be limited by the type of pump you select. Lower flow rates and pipe mounted inline pumps have less efficiency than base mounted end suction pumps at larger capacities. Selecting the type of pump must come first.

Pump Efficiency at Design

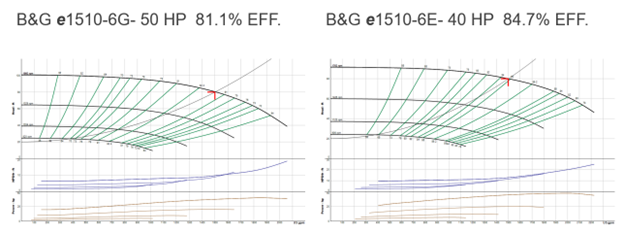

Traditionally, pump schedules would show the pump efficiency at the design conditions. A series of pump selections on a list may show many selections with different efficiencies. Look at the two pumps above.

The one on the right has an efficiency of 84.7% at the design condition of 1500 GPM at 80 feet. The one on the left has an efficiency of 81.1% at the same capacities. In addition, the one on the left will cost 6%more than the one on the right. Which one would you select?

Pump Efficiency During Variable Speed Operation

Bell & Gossett created a variable speed efficiency criterion. Here is the introduction explaining it in their own words:

To address this demand and the industry’s evolution, Bell & Gossett (B&G), a Xylem brand, has introduced a new pump selection criterion called Part Load Efficiency Value (PLEV). PLEV is a calculation that represents the efficiency of the pump at partial flow rates and can be used to gauge true pump performance within a hydronic system.

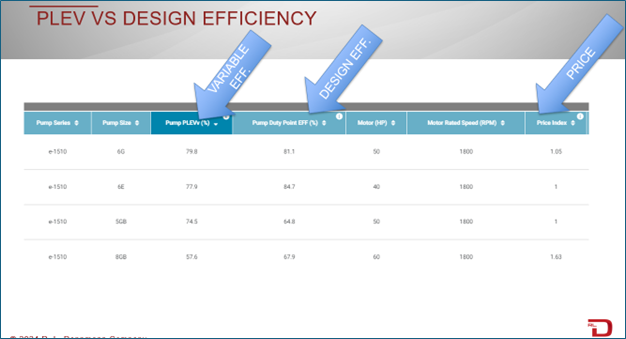

You may click on the link and read the whole story, but B&G knew that pumps only operate at 100% of design a small fraction of the time. They looked at efficiency and hours of operation at 25%, 50%, 75%, and 100% of the design flow rate and created the new efficiency. When you select variable speed pumps in ESP Systemwize you are offered both the design point efficiency and the PLEV efficiency. Look at the difference here.

So, the part load and variable speed story shows an energy savings by investing 5% more in the pump. The savings at 22 cents per KWH and 180 days of operation would be about $200 per year. The payback would be less than 3 years. BUT…the motor is 50 HP so there is more cost in the drive and electrical. Is it worth it? You are the engineer, so make the choice. B&G gives you that option.

Part Load Efficiency Value from Bell and Gossett

Bell and Gossett Part Load Efficiency Value: How to use PLEV

Bell & Gossett Part Load Efficiency Value Part 3: HVAC Pump Selection

Step Five: Design Point on the Curve

The fifth pump selection criteria is the operating point on the curve. How close to the end of the curve should you select a pump? First, let’s be clear. The manufacturer guarantees the operation at any point on the curve if it is not below the minimum flow rate. That means even the last little point at the end of the curve is still OK with the manufacturer.

The issue is the next statement. The warranty is void if damage or incorrect operation occurs off the end of the curve. You cannot extrapolate and extend past the last published duty point.

We know that the variable speed heating, cooling, and plumbing systems are very dynamic. We also, as engineers, do our best to anticipate operation points as two-way valves and zones operate from fully open to full closed and everywhere in between. We also assume the system is balanced and the owner will not adjust the settings. Given all of that, it is still possible for the operating point to move to the right.

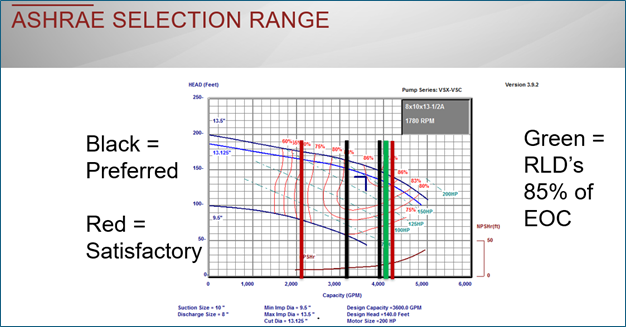

ASHRAE 2020 HVAC Systems and Equipment handbook chapter 44 identifies a satisfactory pump selection range of 66% to 115% of the best efficiency point for the pump. They also suggest a preferred range of 85% to 105% for the best efficiency point. In other words, pick a pump at the best efficiency. R.L. Deppmann suggests you add a caveat to that, “but no farther than 85% or 90% of end of curve”. Look at this curve.

You will find that most of the Bell & Gossett pumps will meet both the ASHRAE and RLD suggestions. Here is an old constant speed curve where there is a slight difference. Many pump manufacturers will offer selections close to the end of curve. We suggest you use the ASHRAE suggestions. Then, additionally, stay no closer than 85% of the end of curve if you don’t have confidence in the pump head and purposefully overhead by more than 15-20% including safety factor. You may use 90% of the end of curve if you are confident that your calculations are accurate. We are amazed how many pump head calculations are scheduled at 100, 125, and 150 feet exactly!

Of course, never operate at less than the minimum flow of the pump.

Bell & Gossett Part Load Efficiency Value Part 4: End-of-Curve Selections

Pump Selection Criteria – Pump Curve

Step Six: Room to Move

This selection thought is for the engineer that is worried about not having enough in the pump calculations. They want to have room to move if they need more capacity. This comes as specification points that eliminate using the largest impeller or best selection. They select back on the curve and may add a significant safety factor to the pump head. All these things make a bad pump selection.

You may also need room for future additions to the system. Remember in a variable speed pump selection that you can overspeed a pump. That requires you to have enough horsepower on the pump. Remember, the horsepower increases as the capacity does. Here are a couple of blogs to scan.

How to Pick an HVAC Centrifugal Pump: Over speeding HVAC Pumps & Motors

Variable Speed Hydronic Pump Selections: Largest Impeller?

Step Seven: Other Thoughts

There are a few other things to consider. The owner may have their own specifications for what they want. Is the pump mounted outside and subject to inclement weather? Does the system require special materials of construction? Does the area have specific requirements such as explosion proof or enclosed construction? Are there any code issues? There may be more. These must also enter the selection.

Variable Speed Hydronic Pump Selections: Largest Impeller?

Hydronic System Pump Selection: Flat vs. Steep Pump Curves

Bell & Gossett ESP-Systemwize Pump Selections

Pump Selections Using Bell & Gossett ESP-Systemwize Part 2

Bell & Gossett ESP-Systemwize Part 3 – Documents

Your B&G representative stands ready to help you to gain confidence in your selections and how to specify so you get what you are expecting. Hope these seven selection steps help you in your design and operation of centrifugal pump systems.