For the contractor, grouting affects the upfront cost for installing the equipment. This is a short term cost but should be considered an investment.

Grouting – Yes or No?

There is an age-old conundrum that HVAC contractors often face:

“To grout or not to grout? That is the question.”

At R. L. Deppmann, we most often hear that the answer hinges on the additional installation cost.

Costs Affiliated With Grouting

For the contractor, grouting affects the upfront cost for installing the equipment. This is a short term cost but should be considered an investment. The end user is interested in lower maintenance repair cost down the road. So, while it is less expensive in the short term to skip grouting, it actually costs more in the long run with ongoing maintenance and callback costs.

Understanding and being able to explain the advantages of grouting to your customers can provide an additional sales opportunity for savvy HVAC contractors, which helps you stand out from the competition.

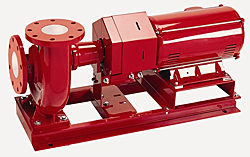

Making The Case for Grouting A Base Mounted Pump

In the following article from Roy Ahlgren – consultant to the hydronic industry and former director of the Bell & Gossett Little Red Schoolhouse – Roy addresses the importance of grouting as an industry standard in strengthening and stiffing the pump base.

In addition to strength and stiffness, grouting locks the pump base to the foundation, making it heavier. This helps maintain the shaft-to-shaft alignment, reducing wear on the moving parts. Proper alignment minimizes wear on parts, which helps reduce the repair cost down the road for the end user. And, the heavier base is, the less likely it will be to transmit vibration and noise to the building. This helps eliminate additional callbacks.

Have questions? Need more information? Call Us at 800.589.6120.